Additional Results from the 2021 Drill Program at the Arctic Project; Two More High-Grade Infill Holes Intersected Within the Heart of Arctic

anuary 25, 2022

January 25, 2022 – Vancouver, British Columbia – Trilogy Metals Inc. (TSX, NYSE American: TMQ) (“Trilogy” or the “Company”) is pleased to announce the third set of drilling results from the 2021 summer field season at the Arctic Project, part of the Upper Kobuk Mineral Projects (“UKMP”) located in northwestern Alaska managed by Ambler Metals LLC (“Ambler Metals”), the joint venture operating company equally owned by Trilogy and a wholly owned subsidiary of South32 Limited (ASX, LSE, JSE: S32; ADR: SOUHY) (“South32”).

The 2021 Arctic drill program included 4,131 meters of diamond drilling, comprising 18 holes, that were designed to convert a portion of the resources from the Indicated category to the Measured category, and provide material for metallurgical testing and geotechnical information. The assay results detailed here are for the second set of infill/metallurgical drill holes from the 2021 summer field season.

On November 22, 2021, the Company released the assay results for two geotechnical drill holes AR21-0173 and AR21-0175 that intersected high-grade mineralization beyond the currently designed pit at Arctic. Subsequently on November 29, 2021, the Company released additional drilling results from two infill holes drilled early in the 2021 field season. Of note is drill hole AR21-0176 which intersected 19.91 meters of almost 12% copper equivalent. For more information on these drilling results, please visit the Company’s website at https://trilogymetals.com/news-and-media/news/.

The results of the remaining 12 holes are expected to be announced over the next couple of months.

Highlights from the second set (two holes) of metallurgical/infill drill holes from the 2021 drill program

Based on a cut-off grade of 0.5% copper equivalent, significant zones of high-grade copper, zinc, lead, gold, and silver mineralization were intersected, including:

- Hole AR21-0182 intersected six mineralized intervals, including 27.65 meters of 2.75% copper, 2.65% zinc, 0.46% lead, 0.66 g/t gold and 42.81 g/t silver for a copper equivalent grade of 4.67% and 10.91 meters of 3.31% copper, 8.22% zinc, 1.78% lead, 0.81 g/t gold and 70.85 g/t silver for a copper equivalent grade of 8.07%; and

- Hole AR21-0184 intersected two mineralized intervals, including 14.46 meters of 1.96% copper, 5.57% zinc, 1.71% lead, 0.73 g/t gold and 51.13 g/t silver for a copper equivalent grade of 5.50%.

All reported intervals are thought to be close to the true width and therefore represent the actual thickness of mineralization.

Tony Giardini, President and CEO of Trilogy, commented, “As we keep drilling into the Arctic Project area, we keep getting more pleasant surprises from the assay lab as the infill results continue to demonstrate very high polymetallic grades over very compelling widths. I look forward to seeing the results from the remaining 12 drill holes from the 2021 field season and I also look forward to the upcoming 2022 field season which will begin in the June.”

Richard Gosse, Trilogy’s Vice President, Exploration stated, “The exciting results from holes AR21-0182 and AR21-0184 confirm the high copper and zinc grades over mineable widths that are to be expected from the infill drill program at Arctic. Good continuity of grade and thickness, such as what we are seeing at Arctic, are characteristic of world-class volcanogenic massive sulphide deposits. We are looking forward to more results like these that will be used to estimate the first measured resource at Arctic.”

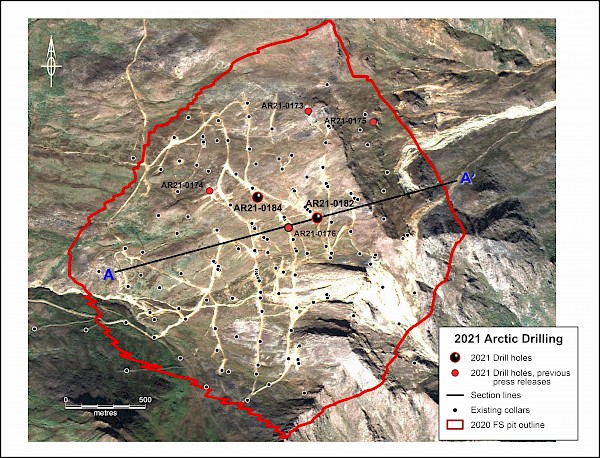

All four infill holes drilled so far during the 2021 program contain mineralized intervals consistent with previous drilling conducted within the resource area on the property. Significant mineralized intervals of high-grade mineralization at a cut-off of 0.5% copper equivalent are reported in Table 1. The locations of the holes are shown in Figure 1 and Table 2.

Of the 18 holes drilled at Arctic last summer, eight holes were for the geotechnical program. The 10 remaining drill holes were part of the infill/metallurgical program, with three of the 10 drill holes also being used for the hydrology program.

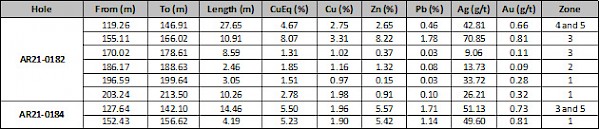

Table 1. Drill Intercepts from the 2021 Arctic Infill Drilling Program

Notes:

- Copper equivalent (CuEq) calculations use metal prices assumptions of US$3.00/lb for copper, US$1.10/lb for zinc, US$1.00/lb for lead, US$1,300/oz for gold, and US$18.00/oz for silver.

- Results are core intervals and not true thickness; true widths have not been determined for the above intercepts but are believed to be representative of actual drill thicknesses.

- Significant interval defined as a minimum of 1.0-meter copper interval with average grade >0.5% CuEq.

- Cut-off grade of 0.5% CuEq.

- Internal dilution up to three meters of <0.5% CuEq.

- Intervals of <1.0 meter not reported.

- Core recovery averaged 96%.

- Minimum sample length was 0.17m, average sample length was 2.4m overall and 1.7m within mineralized zones.

- Some rounding errors may occur.

The reported intervals are based on a copper-equivalent grade of 0.5% using metal prices from Trilogy’s 2020 Arctic feasibility study (US$3.00/lb copper, US$1.10/lb zinc, US$1.00/lb lead, US$1,300/oz gold, and US$18.00/oz silver) and a maximum of 3-meters internal dilution. All drill hole intercepts are close to true width.

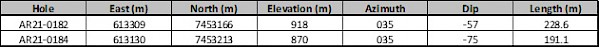

Table 2. Drill Hole Locations at the Arctic Project

Coordinates are in UTM Zone 4N (meters) coordinate system, NAD83 Datum.

Figure 1. Location of Drill Holes from the Arctic Infill Drilling Program

Hole AR21-0182 which is sized PQ3 (83 mm diameter), seen in Figure 2, was designed to provide metallurgical test material as well as to upgrade confidence in the resource model. The hole was collared in the center of the Arctic deposit and intercepts multiple mineralized zones.

Hole AR21-0184 which is sized HQ3 (61 mm diameter), was also designed to provide metallurgical test material, upgrade confidence in the resource model and allow for hydrology monitoring instruments to be installed down hole. The hole was collared in the center of the Arctic deposit and intercepts multiple mineralized zones.

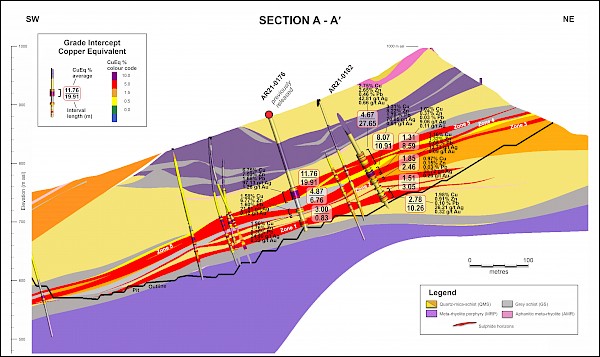

Figure 2. Cross Section Showing Drill Hole AR21-0182

Mineralization within the highest-grade portions of Zones 5 and 4 of drill hole AR21-0182 consists of 30-55% chalcopyrite, 10-15% sphalerite and 5-30% pyrite. Whereas within the highest-grade portions of Zone 3, mineralization consists of 30-55% chalcopyrite, 20-30% sphalerite and 10-20% pyrite. Mineralization within the high-grade portions of Zone 1 consists of 5-25% chalcopyrite, 2-5% sphalerite and 5-15% pyrite.

Mineralization within the highest-grade portions of Zones 3 and 5 of drill hole AR21-0184 consists of 3-10% chalcopyrite, 5-35% sphalerite and 5-30% pyrite. Whereas mineralization within the highest-grade portions of Zone 1 consists of 1-10% chalcopyrite, 10-20% sphalerite, 3% galena and 12-30% pyrite.

All percentages of sulphide mineralization are based off the visual estimations in the core.

Within the Arctic deposit, mineralization occurs as stratiform semi-massive sulphide to massive sulphide beds within primarily chlorite schists and fine-grained quartz schists. The sulphide beds average 4 meters in thickness but vary from less than 1 meter up to as much as 20 meters in thickness.

QA/QC Program

The drilling program, sampling and assaying protocol, and data verification were managed by qualified persons (QPs) employed by Ambler Metals. The diamond drill holes were completed using PQ3 or HQ3 diameter core, and recoveries averaged 95%. Drill core was cut lengthwise into halves using a diamond saw, one-half was used to construct composites for metallurgical testing and one-half was cut lengthwise to provide quarter core for sampling. The remainder of the core was retained in core trays and archived at site.

Samples were collected through mineralized zones using a 0.3 m minimum length and 2.5 m maximum length; average sample length is 1.62 m. Weights of the drill core samples range from 0.81 to 17.31 kg, depending on the size of core, rock type, and recovery.

Each core sample was placed into a bag with a numbered tag and quality control samples were inserted between core samples using the same numbering sequence. Then, samples were grouped into batches for shipping and laboratory submissions. Each batch of 20 samples contains three quality control (QC) samples that comprise one certified reference material (CRM), one core blank (BLK), and one core or crushed duplicate (DUP). Chain-of-custody records are maintained for sample shipments and the custody is transferred from Ambler Metals’ expeditor to the laboratory upon delivery.

Samples were shipped to ALS Minerals’ laboratory in Fairbanks, Alaska, USA, for sample preparation. ALS Minerals Fairbanks is a satellite sample preparation facility accredited under ALS Minerals. After preparation at ALS Minerals Fairbanks, split pulp samples were shipped to ALS Minerals in North Vancouver, B.C., Canada, for assaying. ALS Minerals North Vancouver is an independent laboratory certified under ISO 9001:2008 and accredited under ISO/IEC 17025:2005 by the Standards Council of Canada. ALS Minerals includes its own internal quality control samples comprising certified reference materials, blanks, and pulp duplicates.

Drill core samples were weighed (WEI-21), dried if excessively wet (DRY-21), coarse jaw crushed to 70% passing 6 mm (CRU-21), fine jaw crushed to 70% passing 2 mm (CRU-31), riffle split to 250 g subsamples (SPL-21) and pulverized to 85% passing 75 μm (PUL-31). Crushed duplicates were created by riffle splitting crushed samples into two parts.

Gold analyses were completed using a 30 g lead fire assay and AAS finish (Au-AA23). Multi-element analyses for 48 elements were completed using a geochemical four-acid digestion and ICP-ES/MS finish (ME-MS61). Over-range assays for silver, copper, zinc and sulfur were completed using an ore grade four-acid digestion and ICP-ES finish (ME-OG62). Additional analyses were completed for barium and mercury.

Gold, silver, copper, lead and zinc assays for QC samples were reviewed to ensure that CRMs are within tolerance limits specified on supplier certificates, BLKs are below acceptable thresholds, and DUPs display statistical patterns normally expected for sample types, methods, and elements. CRMs that returned assays outside of tolerance limits and BLKs with assays above thresholds were deemed to have failed. Sample batches containing failed QC samples were re-assayed to ensure that the QC samples returned acceptable results before release. All QC monitoring data are reviewed and signed off by an independent QA/QC geologist.

There is no known relationship between core sample recoveries and assay grades. Ambler Metals will submit 5% of the assay intervals from prospective lithologies to a laboratory independent of ALS Minerals for check assaying.

Qualified Person

Richard Gosse, P.Geo., Vice President, Exploration for Trilogy, is a Qualified Person as defined by National Instrument 43-101. Mr. Gosse has reviewed the scientific and technical informationin this news release and approves the disclosure contained herein.

About Trilogy Metals

Trilogy Metals Inc. is a metal exploration and development company which holds a 50 percent interest in Ambler Metals LLC which has a 100 percent interest in the Upper Kobuk Mineral Projects (“UKMP”) in Northwestern Alaska. On December 19, 2019, South32, a globally diversified mining and metals company, exercised its option to form a 50/50 joint venture with Trilogy. The UKMP is located within the Ambler Mining District which is one of the richest and most-prospective known copper-dominant districts located in one of the safest geopolitical jurisdictions in the world. It hosts world-class polymetallic volcanogenic massive sulphide (“VMS”) deposits that contain copper, zinc, lead, gold and silver, and carbonate replacement deposits which have been found to host high-grade copper and cobalt mineralization. Exploration efforts have been focused on two deposits in the Ambler Mining District – the Arctic VMS deposit and the Bornite carbonate replacement deposit. Both deposits are located within a land package that spans approximately 181,387 hectares. Ambler Metals has an agreement with NANA Regional Corporation, Inc., an Alaska Native Corporation that provides a framework for the exploration and potential development of the Ambler Mining District in cooperation with local communities. Trilogy’s vision is to develop the Ambler Mining District into a premier North American copper producer.

Company Contact

Patrick Donnelly

Vice President, Corporate Communications & Development

pa**************@tr***********.com

604-630-3569

This press release was originally posted on the website of Trilogy Metals Inc. | Home