🇨🇦 Fireweed Metals Announces Mineral Resources For The Mactung Project: The Largest High-Grade Tungsten Deposit In The World

Press release from Fireweed Metals

- Mactung is the world’s largest high-grade deposit of the critical mineral tungsten*.

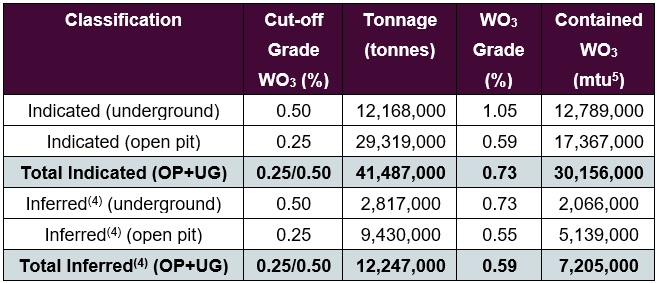

- Mineral resources total 41.5 Mt Indicated Resource at 0.73% WO3 and 12.2 Mt Inferred Resource at 0.59% WO3.

- In addition, an Exploration Target is estimated at 2.5 Mt to 3.5 Mt at a grade between 0.4% and 0.6% WO3, within the mining shapes that constrain the Mineral Resource.

- The resource estimate includes estimates for the critical mineral copper in addition to gold and metallurgical test work is underway to determine recoveries of these by-product metals.

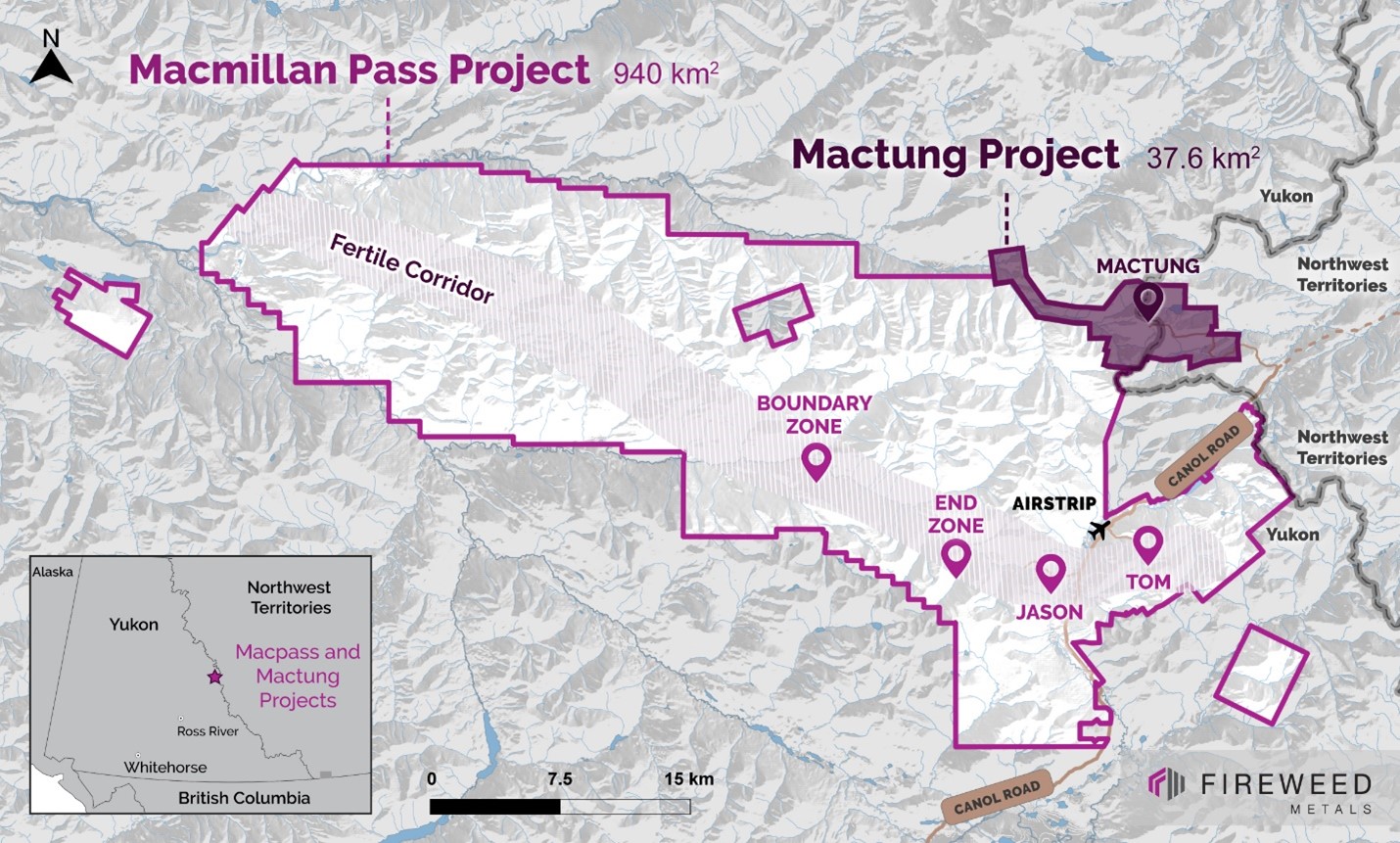

- Mactung is contiguous with Fireweed’s Macmillan Pass zinc-lead-silver project, accessible by the North Canol Road, and provides potential for future project synergies.

Vancouver, British Columbia: FIREWEED METALS CORP. (“Fireweed” or the “Company”) (TSXV: FWZ; OTCQB: FWEDF) is pleased to announce a new mineral resource estimate for its Mactung Project located in Yukon and Northwest Territories, Canada (Map 1), within the Traditional Territories of the Kaska Dena Nation and First Nation of Na-Cho Nyäk Dun, and the Sahtú Settlement Area.

CEO Statement

Brandon Macdonald, CEO, stated “In one year we have gone from signing an initial Letter of Intent to a Definitive Asset Purchase Agreement to the publication of new mineral resource for Mactung. We have taken the historic resource through a process involving relogging, resampling, and a rigorous, modern estimation methodology, and confirmed an impressive and world-class tungsten resource at Mactung*. This not only reaffirms Mactung’s unmatched combination of grade and scale but establishes it as a truly strategic critical minerals project for the West with the underground resource alone able to supply much of North America’s expected demand for decades. Fireweed is looking forward to collaborating with federal, territorial, and Indigenous governments to advance Mactung through the permitting and detailed engineering stages of this unique project.”

Table 1: Mineral Resource Statement(1,2,3,4) for the Mactung Project.

For table footnotes 1, 2, 3, 4, and 5 see page 9.

Mineral Resource Estimate

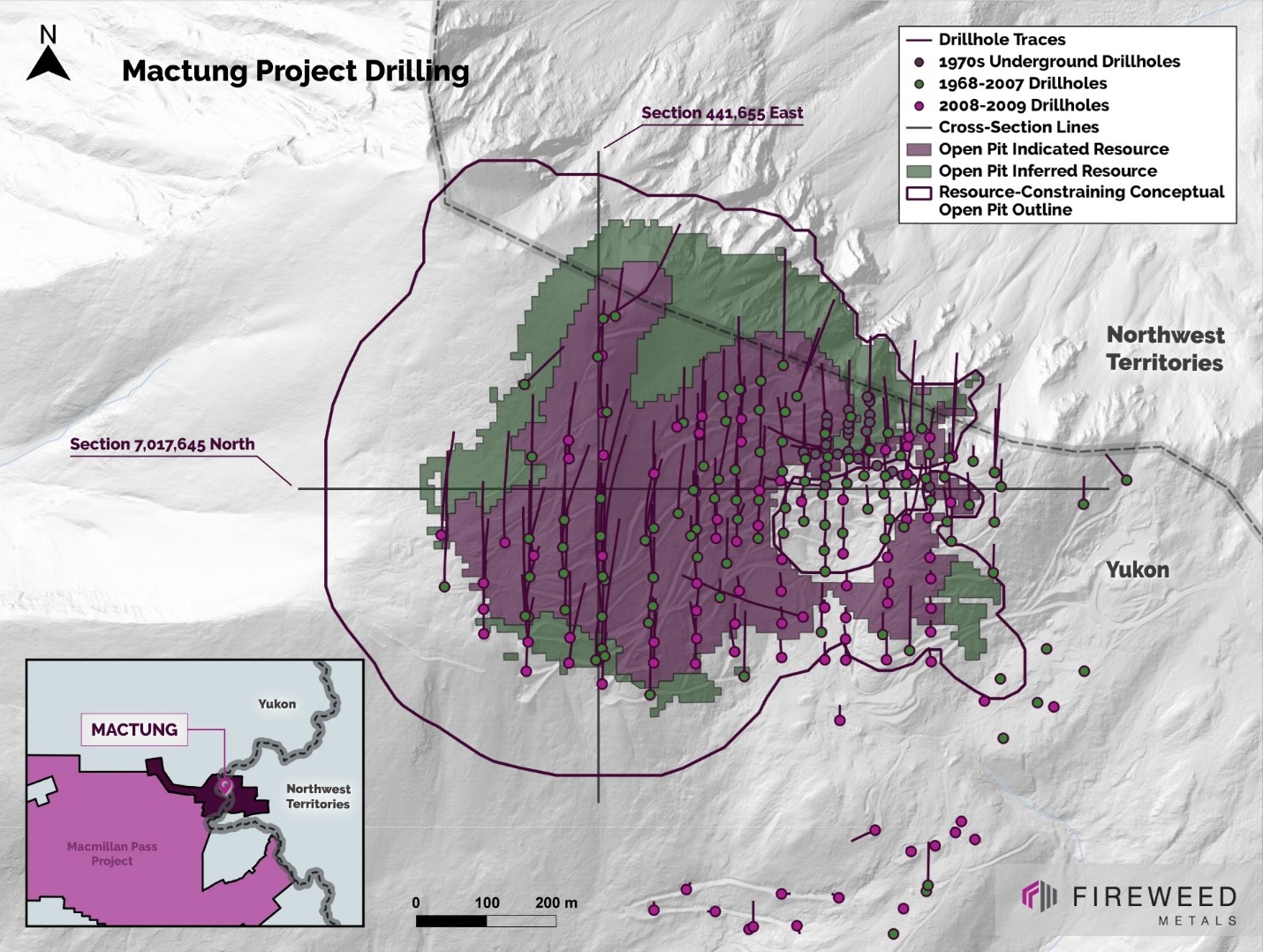

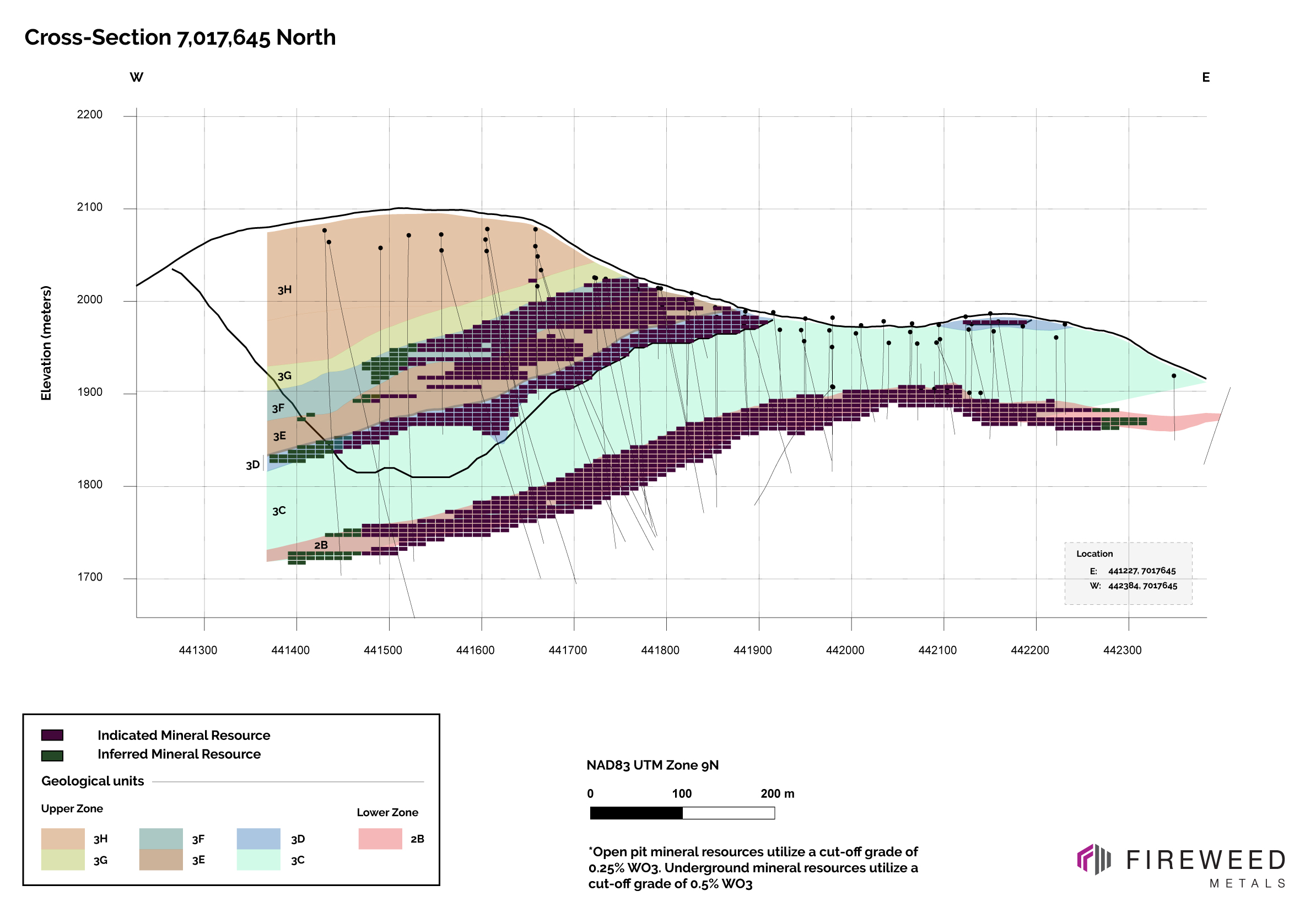

The current Mineral Resource at Mactung ranks it the largest high-grade tungsten resource in the world and it is a clear statistical outlier in terms of grade and contained metal*. It is a tungsten skarn deposit associated with Tombstone-Tungsten suite granitic intrusions that are more broadly linked to a variety of gold and tungsten deposits across Yukon-Northwest Territories. The Mactung deposit is sub-divided into an upper and lower zone that both occur at surface and extend to depths of approximately 400 m below surface.

A very high-grade portion of the resource was constrained by underground mining volumes at a 0.5% WO3 cut-off grade, within the gently to moderately dipping, roughly tabular, lower zone that is approximately 20-30 m thick, extending for a kilometre in strike and up to 380 m down-dip.

In the upper zone, a high-grade open pit resource was constrained by a conceptual pit shell at a 0.25% WO3 cut-off grade.

The Mineral Resource estimate considers and employs reasonable prospects for eventual economic extraction, is applied within classification domains that are continuous, and uses a classification scheme involving a drill spacing that was based on drill-spacing studies. Additional bulk density and assay data were collected during an extensive Fireweed campaign of re-sampling historic drill core in late 2022 and early 2023, and a new geological interpretation of the deposit has been made. These factors have resulted in a robust estimate of the Mineral Inventory at Mactung, providing a solid foundation for future mine development studies.

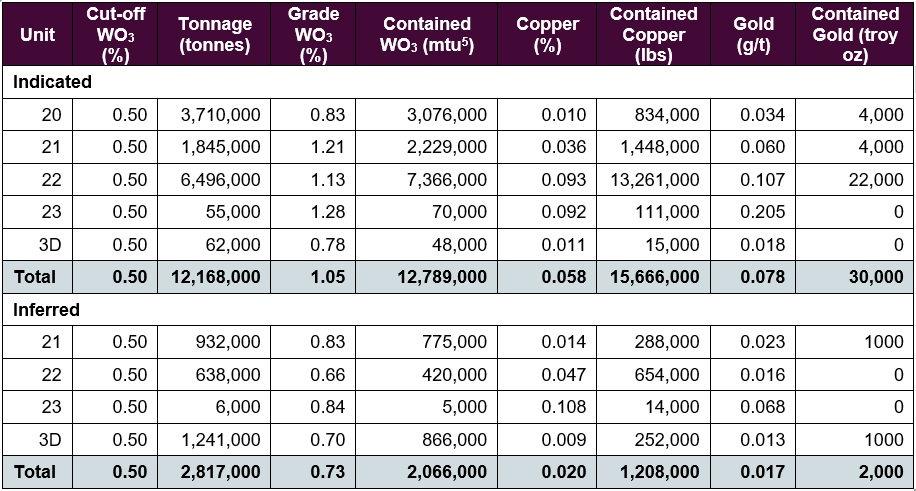

Copper and gold by-product reporting

Copper and gold were estimated as by-product metals for underground constrained resources only (Table 2). No metallurgical test work has been conducted to assess the recovery of copper or gold at Mactung. Based on historical production of small quantities of gold and of copper concentrate from the geologically similar Cantung mine†, it has been reasonably assumed that gravity separation and a copper circuit could be incorporated into the flowsheet to recover a portion of the gold and copper in the Current Mineral Resource to satisfy the reasonable prospects of eventual economic extraction. Fireweed and its consultants are currently completing metallurgical test programs to validate the recovery of tungsten and assess the recovery of gold and copper at Mactung. Grades of copper and gold were considered too low to include within the Mineral Resource Statement for open-pit constrained resources.

Table 2: Copper and gold by-product metals for underground mineral resources subdivided by geological unit(1,2,3,4)

For table footnotes 1, 2, 3, 4, and 5 see page 9.

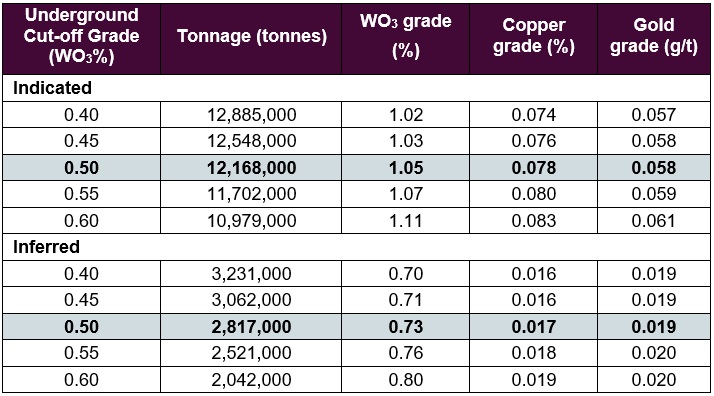

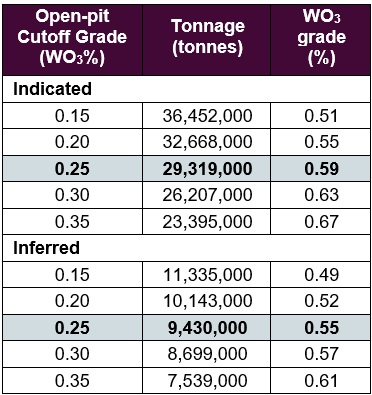

Sensitivity to Cut-Off Grade

A range of cut-off grades were applied to the estimate within the mining volumes established for open-pit and underground resources (Tables 4 and 5).

Table 3: Sensitivity to Underground Cut-Off Grade (Current Resource Highlighted) (2,4)

For table footnotes 2, and 4 see page 9.

Table 4: Sensitivity to Open-pit Cut-Off Grade (Current Resource Highlighted) (2,4)

For table footnotes 2, and 4 see page 9.

Cut-Off Grade and Prospects for Eventual Economic Extraction

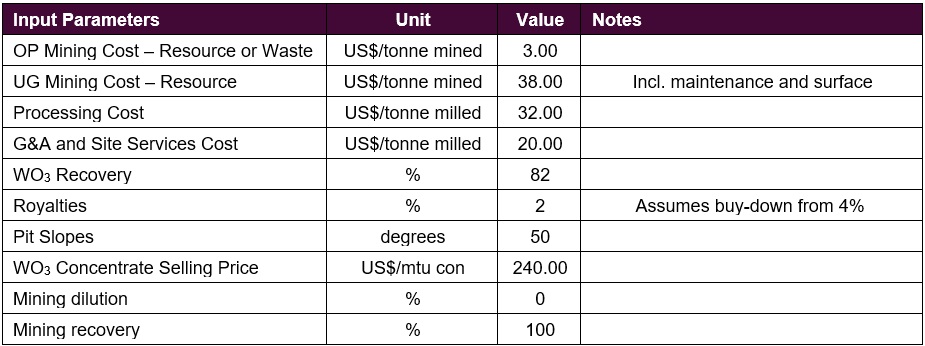

The cut-off grades of 0.5% WO3 for underground mining and 0.25% WO3 for open-pit mining were selected based on a tungsten concentrate price assumption of approximately USD$240/mtu, supported by updated estimates from trading companies that specialize in tungsten, and preliminary estimates of operating costs (Table 5).

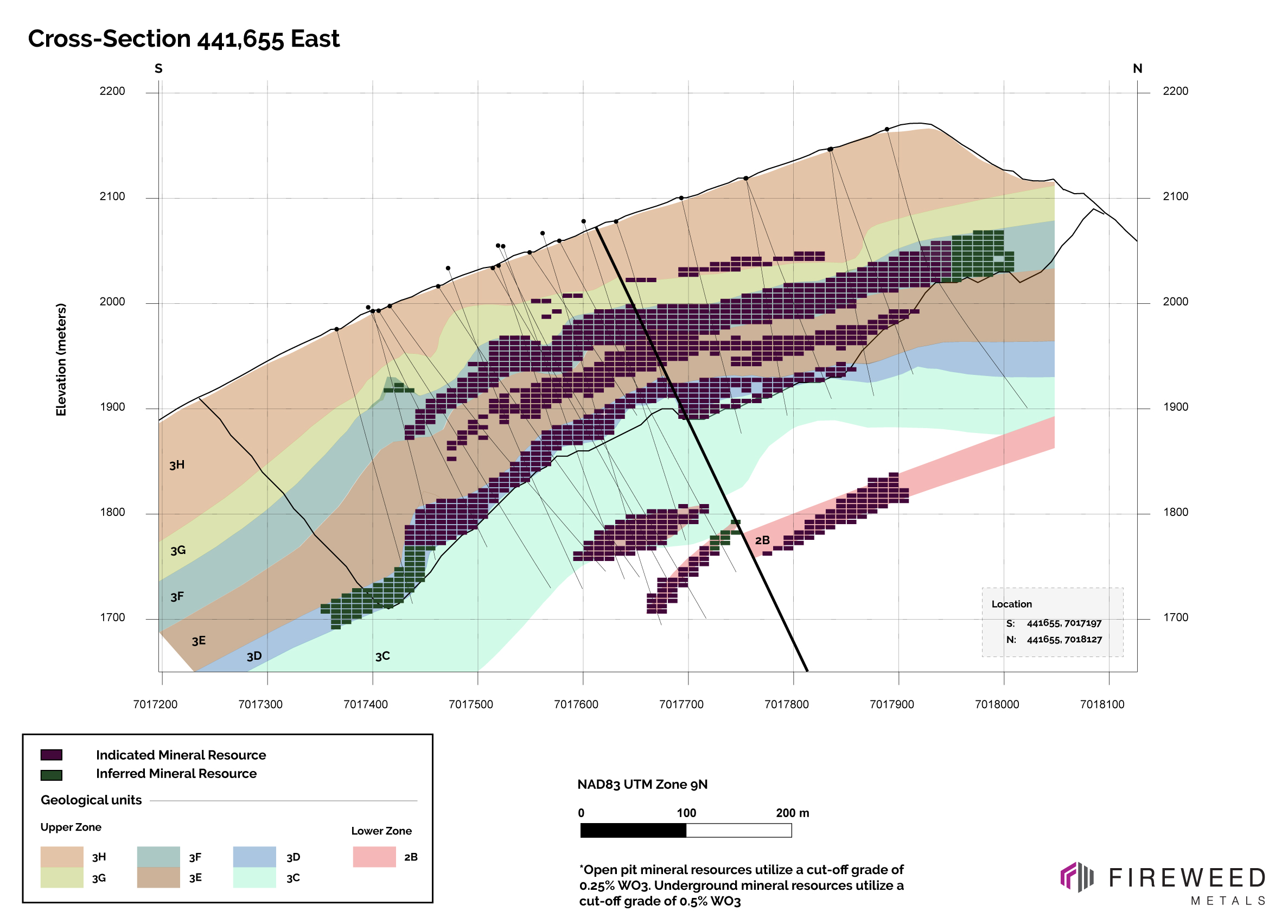

Reasonable prospects for eventual economic extraction of the mineral resources, as required by NI43-101, were demonstrated by developing underground constraining volumes, conceptual pit shells using a Lerchs-Grossman algorithm and input parameters derived from preliminary cost estimates (see Map 2 and Cross-Sections). Only mineral resources above these cut-offs and within the mineral resource-limiting underground constraining volumes and pits are reported; mineralization falling below this cut-off grade or outside the resource-limiting volumes or pits is not reported, irrespective of the grade. Potential underground resources are constrained initially to only the lower zone (2B unit) and a portion of the upper zone (3D unit) below the pit shell leaving a crown pillar. The potential open-pit resource was optimized for only the upper zone (3C, 3D, 3E, 3F, 3G and 3H units). Gold and copper are considered by‑products and were not utilized in cut-off grades, pit optimizations, underground constraints, or for establishing reasonable prospects of eventual economic extraction. Sensitivity to cut-off grade is reported in Tables 3 and 4 above.

Table 5: WO3 Cut-off Grade Calculation Assumptions

Assumptions used to derive the cut-off grades and define the resource-limiting pits are estimated in order to meet the NI43-101 requirement for mineral resource estimates to demonstrate “reasonable prospects for eventual economic extraction”.

Updated Technical Report

The details of the updated mineral resource estimate for Mactung will be provided in a Technical Report compliant with NI43-101 to be filed on www.sedar.com in the next 45 days.

2023 Mineral Resource Estimate Methodology

The mineral resource estimate for Mactung was completed by Garth Kirkham, P.Geo., of Kirkham Geosystems Ltd. using commercial mine-modeling and geostatistical software and adhering to Canadian Institute of Mining, Metallurgy and Petroleum (CIM) Estimation of Mineral Resources and Mineral Reserves Best Practice Guidelines (adopted by CIM council November 29, 2019). The deposit was segregated into multiple estimation domains based on a revised geological model. The lower zone is hosted by Unit 2B (see Cross Sections), and this is subdivided into four spatial zones (20, 21, 22, and 23). The upper zone is hosted by Units 3C, 3D, 3E, 3F, 3G, and 3H (see Cross Sections). Grades of WO3, copper and gold were estimated using ordinary kriging interpolation of capped composites in multiple estimation passes. Search ellipse orientation and anisotropy were based on structural and geological controls and/or variogram models with first pass major axis search distances generally 100 m, and subsequent pass distances generally 60 m.

Mineral Resources are classified under the categories of Measured, Indicated and Inferred according to CIM Definition Standards for Mineral Resources and Mineral Reserves (Adopted by CIM council May 19, 2014). Mineral resource classification for WO3 was based primarily on an analysis of viability and risk, drillhole spacing and on continuity of mineralization. Inferred and Indicated resources were defined as using increasing thresholds of continuity, confidence, and data density. No Measured resources were defined. Final resource classification shells were manually constructed using interpreted solids. Gold and copper are not classified separately and are reported as by‑products based on WO3 classification. A full description of the modeling methodologies for each deposit will be included in a Technical Report scheduled for release within 45 days.

Mactung Exploration Potential

It is estimated that there is the potential for an Exploration Target at Mactung of between 2.5 and 3.5 Mt at a grade of between 0.4 and 0.6% WO3 in addition to the current Mineral Resources disclosed in this news release. The Exploration Target is within the current geological model, supported by drilling and surface mapping. The Exploration Target includes material located beyond the boundaries of the Inferred and Indicated resource classification but is located within the boundaries of the open-pit shell and underground volumes used to constrain the current Mineral Resource.

The Exploration Target is conceptual in nature and requires additional drilling to test the geological model, grade continuity, and extent of mineralization. It is uncertain if additional drilling will validate the geological potential or fulfill the mining and economic criteria necessary to establish reasonable prospects of eventual economic extraction to lead to the classification of the Exploration Target as Mineral Resources.

Data Validation and QA/QC

Fireweed and its consultants conducted extensive statistical analyses to assess the quality of the pre-Fireweed legacy drill hole data in preparation for this mineral resource estimate. The recent re-assaying program has generally shown the data to be of good quality, but use of historical data still presents certain risks in mineral resource estimation due to historical drilling, surveying, sampling, and assaying methodologies. Data from a selection of assay intervals were checked from each year of historical drilling against the original assay certificate or logs, representing 6% of all samples, and was found to be free of errors with minor exceptions.

Assay standards, blanks and duplicates were monitored in Fireweed’s resampling program and were found to be within acceptable levels of precision and accuracy. Surface assay samples were taken by Garth Kirkham in 2022 and confirm the presence of tungsten in the locations tested. The presence of UV-fluorescent scheelite was confirmed visually in outcrop and in core by the use of a blacklight. A subset of historical collar locations were surveyed by Fireweed personnel using differential GPS and historical drillpad locations were further validated against a Digital Elevation Model derived from a 2022 airborne LiDAR survey with good accuracy.

Mactung Location & History

Mactung straddles the Yukon and Northwest Territories border and is located 13 km north of Fireweed’s Macmillan Pass Project camp and the government-maintained Macmillan Pass airstrip (Map 1). It can also be accessed via the North Canol Road about 230 km from the town of Ross River, Yukon.

Mactung was discovered and staked in 1962 by an Amax company geologist. Extensive drilling, metallurgical testing, and multiple historical resource estimates were completed over the next twenty years. The property changed ownership several times and was subsequently acquired by North American Tungsten Corporation (“NATC”) in 1997. In 2007 NATC published updated mineral resources (see Table 2) and in 2009 published a positive feasibility study (available at www.sedar.com under the NATC profile). The Yukon Environmental and Socio-economic Assessment Board (“YESAB”) Executive Council issued its Referral Report and New Recommendation for Project Number 2008-0304 for the Mactung Mine Project in June 2014. Following a recommendation to Decision Bodies that the Project be allowed to proceed to licensing without review, subject to specific terms and conditions, Decision Documents were issued by the Yukon Government and Federal Government on September 3, 2014 and August 1, 2014, respectively.

Subsequently, in June 2015, NATC filed for and was granted creditor protection mainly related to operation of their Cantung mine located to the south. The Government of Northwest Territories (“GNWT”) purchased the Mactung Project for $4.5 million in 2015, and subsequently obtained a Class 4 Mining Land Use Approval in 2020 for mineral exploration activities in the Yukon. Fireweed recently signed a definitive Asset Purchase Agreement for the Mactung Project with the GNWT (see Fireweed news release dated February 28, 2023 for details).

Mactung Geology & Mineralization

Mactung is a tungsten skarn deposit located on the eastern margin of the Selwyn basin in the Canadian Cordillera’s Tombstone-Tungsten Belt (“TTB”). The mid-Cretaceous TTB spans Alaska, Yukon, and Northwest Territories, and hosts many other significant mineral deposits. The Mactung deposit is associated with Tungsten Suite intrusions that intruded late Precambrian to Palaeozoic age, variably metamorphosed clastic and interbedded carbonate rocks of the Selwyn Basin. The tungsten mineralization at Mactung is comprised mostly of scheelite (CaWO4) and is dominated by calcic mineral assemblages associated with abundant pyrrhotite that developed within permeable limestone units of the Cambrian-Ordovician host rocks near a granite intrusion contact.

About Tungsten

Tungsten is the hardest metal with the highest melting point, which makes it an important and often essential metal for use in the automotive, technology, energy, military, and manufacturing industries. World tungsten production is dominated by China and there is currently limited Western tungsten production, which has led tungsten to be listed as a critical mineral by many governments, including Canada. The Canadian government has developed several initiatives to support and advance the exploration and mining of critical minerals in Canada, including zinc and tungsten.

Sustainability Context

Fireweed respectfully acknowledges that the Mactung Project is located within the Traditional Territories of the Kaska Dena Nation and First Nation of Na-Cho Nyäk Dun, and the Sahtú Settlement Area. For the benefit of present and future generations, Fireweed will conduct mineral development activities in a sustainable manner by working collaboratively with Indigenous groups and local communities, establishing a respectful and safe working environment, achieving a high standard of environmental stewardship, and undertaking studies and implementing measures to address local interests and issues.

Qualified Person Statement

Jack Milton, Ph.D., P.Geo. (BC), Fireweed’s VP Geology, and a Qualified Person as defined under Canadian National Instrument 43-101, approved the technical information in this news release except for information related to the Mactung mineral resource estimates. The re-assaying activities at Mactung carried out by Fireweed were undertaken under the supervision of Jack Milton.

Garth Kirkham, P.Geo., of Kirkham Geosystems Ltd. is the Qualified Person, as defined in National Instrument 43-101, is responsible for the Mactung mineral resource estimate and directly related information as reported herein. He has read and approved the relevant technical portions of this news release related to the mineral resource estimates for which he is responsible.

About Fireweed Metals Corp. (TSXV: FWZ; OTCQB: FWEDF; FSE:20F): Fireweed is a public mineral exploration company on the leading edge of Critical Minerals project development. Fireweed is well-funded, with a current cash position of over C$30,000,000 and is well-positioned to carry out a large 2023 exploration program. The Company has three projects located in Canada:

- Macmillan Pass Project (Zinc-Lead-Silver): Fireweed owns 100% of the district-scale 940 km2 Macmillan Pass project in Yukon, Canada, which is host to one of the largest undeveloped zinc resources in the world* where the Tom and Jason zinc-lead-silver deposits have current Mineral Resources1 (21 Mt Indicated Resource at 6.59% zinc, 2.48% lead, and 21.33 g/t silver; and 39.47 Mt Inferred Resource at 5.84% zinc, 3.14% lead, and 38.15 g/t silver) and a Preliminary Economic Assessment2 (PEA). In addition, Boundary Main, Boundary West, Tom North and End Zone have significant zinc-lead‑silver mineralization drilled but not yet classified as mineral resources. The project also includes large blocks of adjacent claims with known showings and significant upside exploration potential.

- Mactung Project (Tungsten): The Company recently signed a definitive Asset Purchase Agreement and acquired 100% interest in the 37.6 km2 Mactung Project located adjacent to the Macmillan Pass Project. New mineral resources for Mactung described above (5 Mt Indicated Resource at 0.73% WO3 and 12.2 Mt Inferred Resource at 0.59% WO3) make it the world’s largest high-grade resource of the critical mineral tungsten*. Located in Canada, it is one of the rare large tungsten resources outside of China.

- Gayna River Project (Zinc-Lead-Gallium-Germanium): Fireweed has 100% of the 128.75 km2 Gayna River project located 180 kilometres north of the Macmillan Pass project. It is host to extensive mineralization including Critical Minerals zinc, gallium and germanium as well as lead and silver, outlined by 28,000 metres of historical drilling and significant upside potential.

In Canada, Fireweed (TSXV: FWZ) trades on the TSX Venture Exchange. In the USA, Fireweed (OTCQB: FWEDF) trades on the OTCQB Venture Market (www.otcmarkets.com) and is DTC eligible for enhanced electronic clearing and settlement. In Europe, Fireweed (FSE: 20F) trades on the Frankfurt Stock Exchange.

Additional information about Fireweed and its projects can be found on the Company’s website at FireweedMetals.com and at www.sedar.com.

ON BEHALF OF FIREWEED METALS CORP.

“Brandon Macdonald”

CEO & Director

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

Cautionary Statements

Forward Looking Statements

This news release contains “forward-looking” statements and information (“forward-looking statements”). All statements, other than statements of historical facts, included herein, including, without limitation, statements relating to mineral resource estimates and statements relating to deposits and exploration targets, interpretation of drill results, future work plans, world demand and supply of Tungsten, and the potential of the Company’s projects, are forward looking statements. Forward-looking statements are frequently, but not always, identified by words such as “expects”, “anticipates”, “believes”, “intends”, “estimates”, “potential”, “possible”, and similar expressions, or statements that events, conditions, or results “will”, “may”, “could”, or “should” occur or be achieved. Forward-looking statements are based on the beliefs of Company management, as well as assumptions made by and information currently available to Company management and reflect the beliefs, opinions, and projections on the date the statements are made. Forward-looking statements involve various risks and uncertainties and accordingly, readers are advised not to place undue reliance on forward-looking statements. There can be no assurance that such statements will prove to be accurate, and actual results and future events could differ materially from those anticipated in such statements. Important factors that could cause actual results to differ materially from the Company’s expectations include but are not limited to, exploration and development risks, unanticipated reclamation expenses, expenditure and financing requirements, general economic conditions, changes in financial markets, the ability to properly and efficiently staff the Company’s operations, the sufficiency of working capital and funding for continued operations, title matters, First Nations relations, operating hazards, political and economic factors, competitive factors, metal prices, relationships with vendors and strategic partners, governmental regulations and oversight, permitting, seasonality and weather, technological change, industry practices, uncertainties involved in the interpretation of drilling results and laboratory tests, and one-time events. The Company assumes no obligation to update forward‐looking statements or beliefs, opinions, projections, or other factors, except as required by law.

Footnotes and References

*: References to relative size and grade of the Mactung mineral resources and Macmillan Pass mineral resources in comparison to other tungsten and zinc deposits elsewhere in the world, respectively, are based on review of the Standard & Poor’s Global Market Intelligence Capital IQ database.

†: The Cantung Mine, 175 km southeast of the Mactung deposit, operated intermittently from 1962 to 2015 in the Northwest Territories and occurs in the same geological belt as the Mactung deposit – both are skarn deposits associated with Cretaceous age Tungsten Suite intrusions in the Tombstone-Tungsten Belt. During production, the Cantung Mine was the highest-grade tungsten operation in the world, and the largest tungsten mine outside China. See Technical Reports on the Cantung Mine filed by North American Tungsten on www.SEDAR.com for further details.

1: Fireweed Technical Report titled “NI 43-101 Technical Report on the Macmillan Pass Zinc-Lead-Silver Project, Watson Lake and Mayo Mining Districts Yukon Territory, Canada” filed on www.SEDAR.com on February 23, 2018, and Fireweed News Release dated January 10, 2018.

2: Fireweed Technical Report titled “NI 43-101 Technical Report Macmillan Pass Project Yukon Territory Canada” filed on www.SEDAR.com on July 9, 2018, and Fireweed News Release dated May 23, 2018. This Technical Report contains a Preliminary Economic Analysis disclosing an economic analysis of mineral resources that is preliminary in nature and does not include any mineral reserves. It is equally emphasized that the mineral resources disclosed within this Technical Report are not mineral reserves and do not have demonstrated economic viability.

Table Footnotes

- All mineral resources have been estimated in accordance with Canadian Institute of Mining and Metallurgy and Petroleum (“CIM”) definitions, as required under National Instrument 43-101 (“NI43-101”).

- Mineral resources are reported in relation to a conceptual pit shell and underground mining volumes to demonstrate reasonable prospects for eventual economic extraction, as required under NI43-101; mineralization lying outside of the pit shell or underground volumes is not reported as a mineral resource. Note the conceptual pit shell and underground volumes are used for mineral resource reporting purposes only and is not indicative of the proposed mining method; future mining studies may consider underground mining, open pit mining or a combination of both. Mineral resources are not mineral reserves and do not have demonstrated economic viability. Mineral resource estimates do not account for mineability, selectivity, mining loss and dilution. All figures are rounded to reflect the relative accuracy of the estimate and therefore numbers may not appear to add precisely.

- Open pit (OP) mineral resources are reported at a cut-off grade of 0.25% WO3. Underground (UG) mineral resources are reported at a cut-off grade of 0.5% WO Cut-off grades are based on a price of US$240 per mtu of WO3 concentrate and a number of operating cost and recovery assumptions (see Table 5).

- Inferred mineral resources are considered too speculative geologically to have economic considerations applied to them that would enable them to be categorized as mineral reserves. There is also no certainty that these inferred mineral resources will be converted to the measured and indicated categories through further drilling, or into mineral reserves, once economic considerations are applied. The Inferred Mineral Resource in this estimate has a lower level of confidence than that applied to an Indicated Mineral Resource and must not be converted to a Mineral Reserve. It is reasonably expected that the majority of the inferred Mineral Resource could be upgraded to an Indicated Mineral Resource with continued exploration.

- A metric tungsten unit (mtu) is 10 kilograms of tungsten trioxide (WO3).

Contact:

Brandon Macdonald, CEO

Phone: (604) 646-8361

Email: in**@fi************.com

Originally published on 13 June.

Announcements are published as a service to readers. The sender is responsible for all content.

Announcements for publication can be submitted to pr***********@ar**************.com.