Increasing demands on air chilling fully met

Press release from Marel

Marel sets the trend in air chilling

Longer shelf life means chilling to lower core temperatures without, however, thin parts of the bird such as wings and neck skin being allowed to freeze. Creating exactly the right micro-climate around each product becomes ever more critical.

Speed and efficiency

In many markets, the poultry industry has become more concentrated with fewer processing plants handling more products. This is the result both of a drive towards greater production efficiency and advances in processing technology, which have made higher line speeds possible.

Marel is active in the development of air chilling systems, which address all key issues. Marel is the trendsetter in air chilling technology. The company has developed many of today’s state-of-the-art systems, two excellent examples being DownFlow+ and Maturation Shock Chill.

No drying out

One criticism of air chilling systems is that they can dry out product, adversely affecting yield, product presentation and even taste. It was for this reason that Marel developed its DownFlow+ technology, which impacts on all three aspects. The technology consists of misting cabinets placed at specific points in the air chilling tunnel. Their position will vary from plant to plant and will depend on the products offered by the processor. Each misting cabinet can apply a thin film of moisture to all surfaces both external and internal or to one of them only, either external or internal. Cabinets can be switched on and off quickly and easily to give different finishes.

Maturation in line

The Marel Shock Maturation Chilling System chills and matures whole carcasses in-line. This is done to prevent tough breast fillet, when breasts are de-boned. In the days before the system was launched, another Marel first, carcasses were either not matured at all sometimes resulting in tough fillet or were transferred into an off-line maturation store for periods of up to twelve hours.

The Maturation Shock Chill process happens in two stages. In the first shorter stage, whole carcasses are subjected to very cold air circulated at high velocities. This cools all surfaces to stop the growth of spoilage bacteria. Misting cabinets are used both to aid chilling and prevent carcasses from drying out. In the much longer second stage, less cold air is blown onto carcasses at lower velocities, the aim being to keep carcasses for as long as possible in the area of maximum enzyme activity.

Not only is Shock Maturation Chilling fully in-line, saving a manual re-hang operation; it tenderizes breast meat in a much shorter period of time. In conjunction with RapidRigor in-line electric stimulation, installed immediately after plucking, this can be as little as three hours. RapidRigor uses pulses of electricity to remove any energy left in muscles postmortem.

Driving long conveyor systems

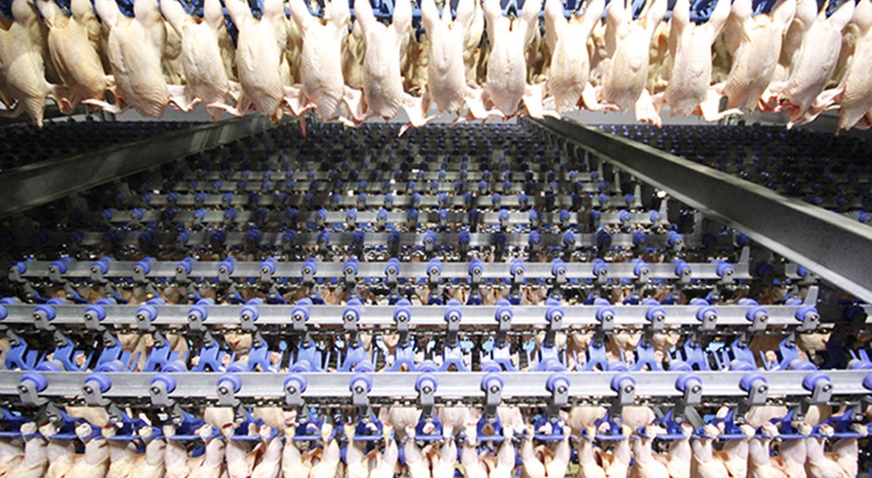

As processing plants strive to get as close to 100% uptime as possible, all components of an air chilling system must be ultra-reliable. Today’s largest processing plants have lines capable of handling 15,000 products per hour. Given a three-hour dwell time in the Shock Maturation Chilling tunnel, this translates into almost 7 km of overhead conveyor and some 45,000 shackles.

It was precisely for this purpose that Marel developed its ATC system (Active Tension Control), the aim being to drive long lines super-reliably hour after hour. Should one of the chiller’s drive motors fail during production, its work is automatically taken over by its neighbor. Normal production can continue until the end of the shift. Today’s system can even pinpoint the position of any broken shackle, allowing plant engineering staff to take quick remedial action.

Full product-by-product traceability

Both retail and fast-food chains are increasingly insisting that their suppliers offer full traceability. With product automatically re-hung into and out of the air chill tunnel, Marel air chilling is fully in line. Each individual product can therefore be accurately tracked and traced through both primary and secondary processes. This is not the case with off-line water chilling systems.

Useful early warning

A SmartWeigher in-line product weigher and an IRIS vision grading system can be installed at the beginning of an air chill tunnel. These will tell plant management the weight and quality grade of each product entering the tunnel. This invaluable information can be used to match products available to customer orders. Plant management can then determine the most profitable destination for each carcass and program software accordingly. Given that products can be in an air chill system for up to three hours, IRIS and SmartWeigher provide a very effective early warning system. If products are not as expected, knowing this situation well in advance allows management to act accordingly.

Always striving for the perfect balance

Air chilling technology will continue to develop. Marel will seek to perfect the balance between temperature and humidity, time and maturation and between energy use and space. Chilling times will shorten and the process will become ever more efficient, encouraging those processors and markets still chilling in water to make the move to air.

Once consumers have tasted an air-chilled product, they are usually convinced and have always been prepared to pay more for it. Not one processor has yet made the move from air back to water. That tells you all you need to know about the technology’s future.

Originally published on 24 January.

Announcements are published as a service to readers. The sender is responsible for all content.

Announcements for publication can be submitted to pr***********@ar**************.com.